Technical Sourcing Guide & Frequently Asked Question. Our Trusted Tannery's Specifications, Logistics, and Compliance for Professional Ateliers.

Compartir

Q1: What exactly does Sunny Exotic Leather mean by "Grade 1 Select"?

The Concern: The Craftsman fears paying for unusable area due to scars or defects.

The Technical Answer: In the exotic trade, grading standards vary wildly between brokers. At Sunny (a division of Anson International), "Grade 1 Select" is a strict internal standard defined by usable surface area for high-end goods.

-

No Center-Cut Defects: The primary belly (Crocodylus) or back (Varanus) area must be free of deep scars, holes, or calcification that would interrupt a main panel cut.

-

Symmetry: Scale patterns must show high architectural balance from left to right.

-

Yield Guarantee: We estimate a 95%+ usable yield for Grade 1 skins, significantly reducing waste compared to industry-standard "Grade B" or "Craft Grade" hides.

Q2: How do you handle international customs and CITES seizures?

The Concern: The Strategist's biggest fear—losing a $5,000 shipment at the border.

The Technical Answer: We view legal compliance as part of the product. We have over 20 years of experience navigating international trade regulations for protected species.

-

Physical Tags: Every regulated skin ships with a tamper-proof, numbered CITES tag attached.

-

Documentation: We generate and include the official CITES export permit validated by Malaysian authorities.

-

The Guarantee: Provided your country allows the import, our paperwork ensures smooth transit. We have never had a properly documented shipment seized due to our error.

Q3: Why should I source "Tannery Direct" from Malaysia instead of a local distributor?

The Concern: The buyer is weighing convenience vs. cost and quality control.

The Technical Answer: Sourcing via distributors involves multiple markups and a loss of provenance. By the time a skin reaches a retail shelf, it may have passed through three hands, each adding 30-50% to the cost while obscuring its origin.

-

Margin Protection: Buying direct from our Perak facility eliminates middleman layers, allowing you to acquire Grade 1 materials at a cost base that maximizes your retail margins.

-

Technical Consistency: You are speaking directly to the source of production, ensuring your specifications regarding thickness and finish are met without translation errors.

Q4: What are the thickness specifications, and are they suited for small leather goods (SLGs)?

The Concern: The Craftsman needs to know if the leather will cooperate with their skiving machine and edge-painting process.

The Technical Answer: Yes. Our standard production is precision-tanned specifically for high-end handbags, wallets, and watch straps.

-

Standard Thickness: Our crocodile and alligator skins generally range between 1.0mm and 1.2mm.

-

Skiving Profile: The fiber density of our Grade 1 skins allows them to be skived down incredibly thin at the edges without tearing, essential for turned-edge construction and refined watch straps.

Q5: How can I trust the quality of a specific skin before I pay for the allocation?

The Concern: The universal fear of buying high-AOV "natural" products online without seeing them first.

The Technical Answer: We do not expect professional ateliers to purchase blindly. For serious inquiries on high-value allocations (such as Himalayan or large Nile Croc), we offer a Digital Pre-Shipment Inspection.

-

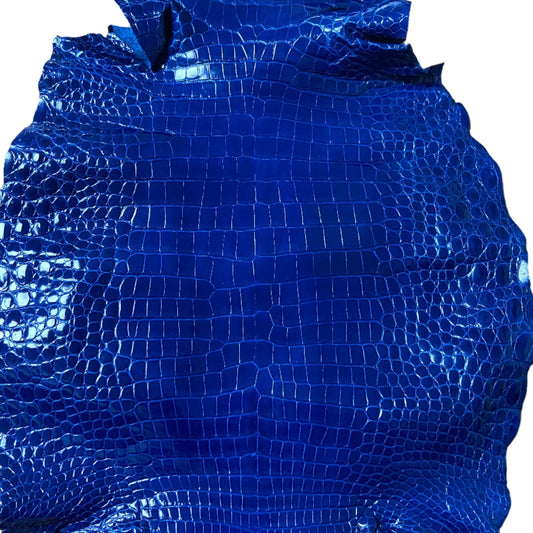

Upon request, our team will provide high-definition video and macro photography of the exact skins assigned to your order, under studio lighting.

-

You can inspect scale grain, verify the absence of defects, and approve the specific gradient before final payment and CITES issuance.