El proceso de bronceado

Compartir

Los primeros procesos importantes del curtido de pieles exóticas son el remojo y el descascarillado. Durante este paso clave, los lotes de pieles (o lotes) se colocan en enormes tanques de paletas llenos de agua y otros materiales de procesamiento que disuelven suavemente la capa escamosa de la piel, mientras que la paleta agita suavemente el agua para "abrir" la piel y estimular el desprendimiento de las escamas. Después de 7 a 10 días, cuando la flor de la piel está expuesta y el pH del agua se ajusta, las pieles están listas para el curtido.

El curtido de las pieles se lleva a cabo en grandes tambores llenos de agua y otras soluciones, una de las cuales es una sustancia curtiente de base mineral llamada "cromo". Las pieles se batirán en los tambores durante los siguientes días.

Una vez que se sacan de los tambores, las pieles han adquirido un estado gomoso y correoso conocido como "wet-blue". Las pieles se mantienen en wet-blue durante un período de varias semanas para garantizar que el curtido esté completo y que el cromo se adhiera firmemente a la piel.

Después de que las pieles hayan "descansado" en la fase de wet-blue, un maquinista las raspa hasta obtener un grosor uniforme operando hábilmente una cuchilla giratoria de alta velocidad. Cada piel se revisa meticulosamente después del raspado para garantizar que se cumplan los estrictos y rigurosos estándares de calidad.

Después del afeitado, las pieles se preparan para la fase de blanqueo, neutralización y recurtido. Las pieles se colocan en grandes tambores donde se eliminan las marcas naturales y el pigmento de las pieles. Todos los radicales libres / ácidos de las pieles se neutralizan y las características exactas del cuero se imparten a la piel mediante la adición de extractos de recurtido sintéticos o vegetales. Finalmente, se agregan aceites de "licor graso" especialmente formulados a las pieles para lograr el tacto perfecto y realzar la belleza del cuero.

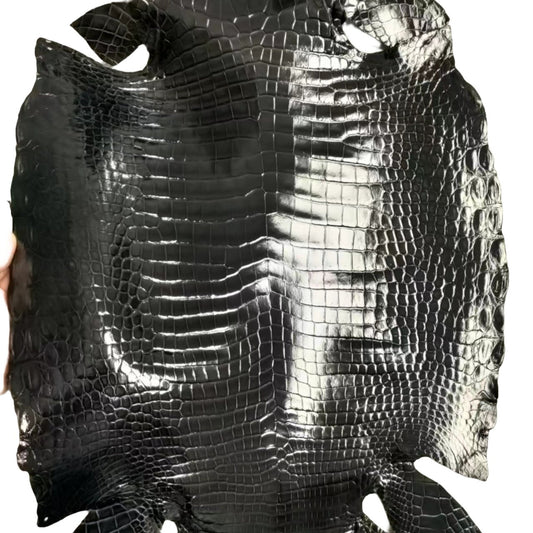

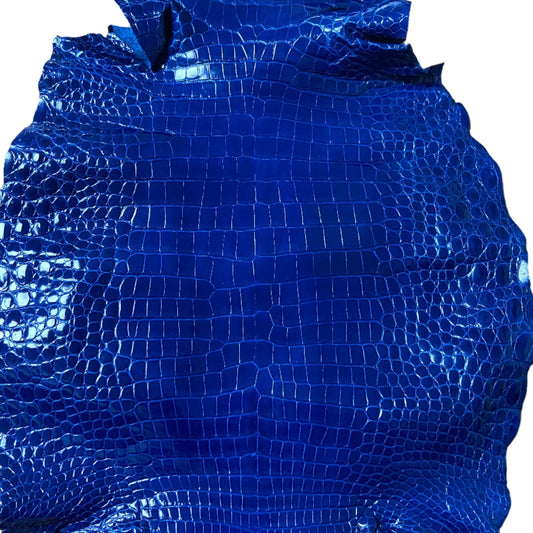

En este punto, se seleccionan las pieles para diferentes opciones de acabado, como Millennium, mate o esmaltado/alto brillo, según los requisitos del usuario final y las necesidades del cliente.

Finalmente, una vez que las pieles pasan nuestro riguroso control de calidad, están listas para ser clasificadas, medidas y empaquetadas. Cada piel es revisada personalmente por un miembro de la familia Plott antes de salir de la curtiduría y recibir el sello de aprobación para ser entregada a nuestros clientes.