A Comprehensive Overview of the Leather Tanning Process

Share

Leather tanning is an intricate and often underestimated aspect of the manufacturing process, which significantly influences the quality of a wide range of products, from apparel like jackets and bags to personal accessories like wallets and the upholstery within automobiles and furniture. The Italian leather industry, renowned for its expertise, stands out globally for its ability to achieve superior tanning results, differentiating between ordinary articles and high-quality ones.

For those seeking a deeper understanding of this crucial process, we present a concise explanation of leather tanning below.

**How Leather Tanning Works**

**Preparation:**

The initial step in leather tanning is the preparation of raw hide. This phase aims to enhance the penetration of tanning agents. It often involves dermal relaxation and partial saponification of fats. Additionally, liming is employed, where hydrated lime, acting as a basic agent, is utilized to remove any remaining hair from the hide's outer surface. The lime and impurities are subsequently purged using water and weak acids to lower the pH to the collagen's isoelectric point—a critical protein addressed during tanning. The final preparation phase, pickling, involves treating the hide with a water-based solution of salt and acid (typically sulfuric or hydrochloric) to achieve a significantly reduced pH, facilitating the penetration of tanning agents.

**Tanning Process:**

The tanning process is pivotal in leather production, as it prevents organic degradation and imparts resistance to mechanical stress and chemical agents. Chromium(III) sulfate is one of the most effective tanning agents, leading to chrome-tanned hides and skins commonly known as "wet blue" due to the light blue hue resulting from this treatment. This process transpires within a drum—a slowly rotating, hollow cylinder that can be opened and closed. Here, the hide is subjected to a solution of the necessary chemical reagents, known as tanning liquor. Throughout the tanning process, the skin is restored to its original thickness, which may have been altered during the prior preparation steps. To achieve uniform thickness, the product undergoes a wet shaving process upon completion of tanning. The tanned and shaved skins are subsequently separated and dried on a roundabout chain, where they remain for approximately half a day.

**Dyeing:**

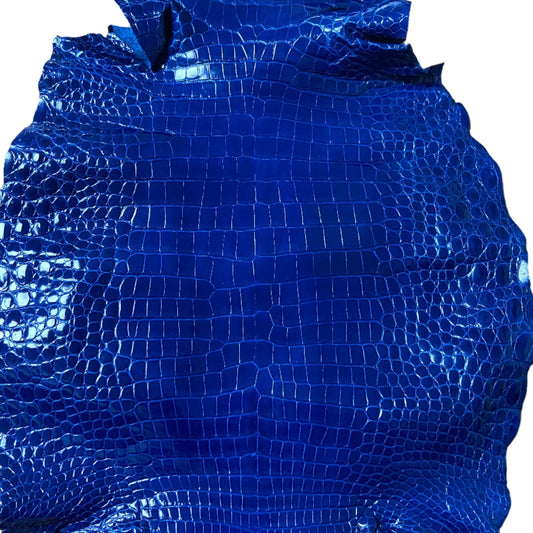

After the drying phase, the skins are meticulously selected, categorized, and stored, ensuring their readiness for orders. Upon receiving an order, the desired finish and color are determined, followed by the dyeing process, which occurs in smaller drums and typically spans just a few hours. Once again, the skins undergo controlled drying at around 35°C, a process lasting approximately half a day. To prevent folds and creases, the skins are hung on clamps.

**Finishing Process:**

The final stage of the leather tanning process is dedicated to achieving the desired finish and enhancing the product's resistance to wear and tear. This phase encompasses a range of mechanical and chemical processes, employed in various combinations to achieve specific outcomes such as smoothness, gloss, a weathered appearance, and more. Options include:

- **Volanatura:** A method involving the use of a rotating drum (without water) to enhance the leather's softness to the touch.

- **Dry Shaving:** Employed to achieve a specific thickness for the leather.

- **Spraying:** Can be either machine-made or hand-applied, tailored to the desired treatment quality.

- **Hand Buffing:** Facilitates deeper color penetration into the leather's natural creases and scales.

- **Discoloration:** This treatment can remove part of the uppermost layer of color, imparting a worn-out appearance.

- **Painting:** A customizable treatment allowing for the creation of various patterns and effects in accordance with customer preferences.

In conclusion, the leather tanning process is a meticulous and multifaceted journey that greatly influences the quality and characteristics of leather products. The Exotic tannery tradition of leather craftsmanship exemplifies excellence in this field, ensuring that leather goods bearing the mark of Italian expertise stand out as symbols of quality and artistry.

For those seeking a deeper understanding of this crucial process, we present a concise explanation of leather tanning below.

**How Leather Tanning Works**

**Preparation:**

The initial step in leather tanning is the preparation of raw hide. This phase aims to enhance the penetration of tanning agents. It often involves dermal relaxation and partial saponification of fats. Additionally, liming is employed, where hydrated lime, acting as a basic agent, is utilized to remove any remaining hair from the hide's outer surface. The lime and impurities are subsequently purged using water and weak acids to lower the pH to the collagen's isoelectric point—a critical protein addressed during tanning. The final preparation phase, pickling, involves treating the hide with a water-based solution of salt and acid (typically sulfuric or hydrochloric) to achieve a significantly reduced pH, facilitating the penetration of tanning agents.

**Tanning Process:**

The tanning process is pivotal in leather production, as it prevents organic degradation and imparts resistance to mechanical stress and chemical agents. Chromium(III) sulfate is one of the most effective tanning agents, leading to chrome-tanned hides and skins commonly known as "wet blue" due to the light blue hue resulting from this treatment. This process transpires within a drum—a slowly rotating, hollow cylinder that can be opened and closed. Here, the hide is subjected to a solution of the necessary chemical reagents, known as tanning liquor. Throughout the tanning process, the skin is restored to its original thickness, which may have been altered during the prior preparation steps. To achieve uniform thickness, the product undergoes a wet shaving process upon completion of tanning. The tanned and shaved skins are subsequently separated and dried on a roundabout chain, where they remain for approximately half a day.

**Dyeing:**

After the drying phase, the skins are meticulously selected, categorized, and stored, ensuring their readiness for orders. Upon receiving an order, the desired finish and color are determined, followed by the dyeing process, which occurs in smaller drums and typically spans just a few hours. Once again, the skins undergo controlled drying at around 35°C, a process lasting approximately half a day. To prevent folds and creases, the skins are hung on clamps.

**Finishing Process:**

The final stage of the leather tanning process is dedicated to achieving the desired finish and enhancing the product's resistance to wear and tear. This phase encompasses a range of mechanical and chemical processes, employed in various combinations to achieve specific outcomes such as smoothness, gloss, a weathered appearance, and more. Options include:

- **Volanatura:** A method involving the use of a rotating drum (without water) to enhance the leather's softness to the touch.

- **Dry Shaving:** Employed to achieve a specific thickness for the leather.

- **Spraying:** Can be either machine-made or hand-applied, tailored to the desired treatment quality.

- **Hand Buffing:** Facilitates deeper color penetration into the leather's natural creases and scales.

- **Discoloration:** This treatment can remove part of the uppermost layer of color, imparting a worn-out appearance.

- **Painting:** A customizable treatment allowing for the creation of various patterns and effects in accordance with customer preferences.

In conclusion, the leather tanning process is a meticulous and multifaceted journey that greatly influences the quality and characteristics of leather products. The Exotic tannery tradition of leather craftsmanship exemplifies excellence in this field, ensuring that leather goods bearing the mark of Italian expertise stand out as symbols of quality and artistry.